Machine Design & Manufacturing

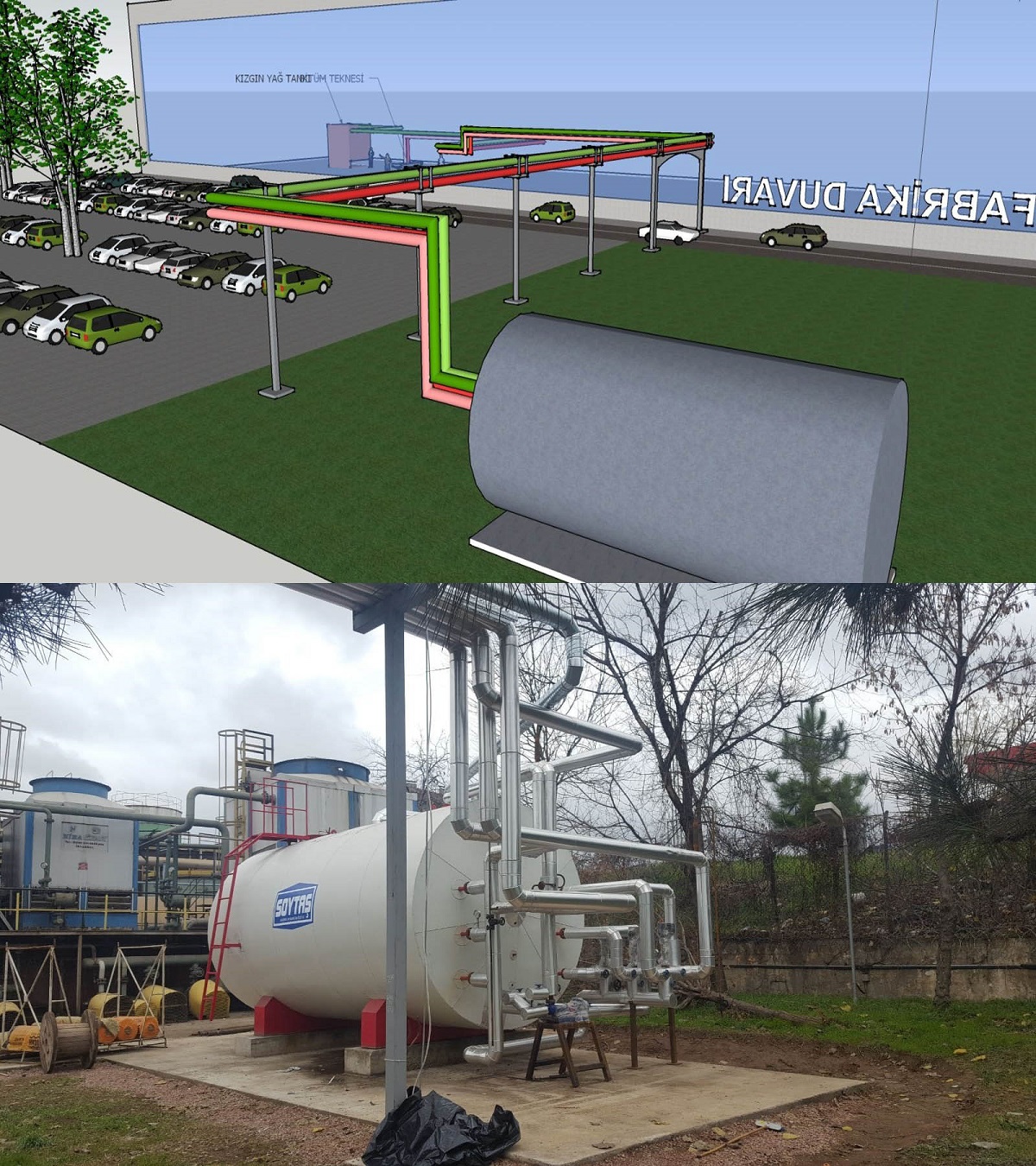

After analyzing and exploring your industrial needs, we are developing a special solution and costing you step by step for your project.

We then go to the computer aided design stage and provide you with the most suitable design samples and additional options.

After the testing process, we are performing your installation and providing continuous support for your machine at the time of need.

We provide all service from start to finish, turnkey delivery by our company.

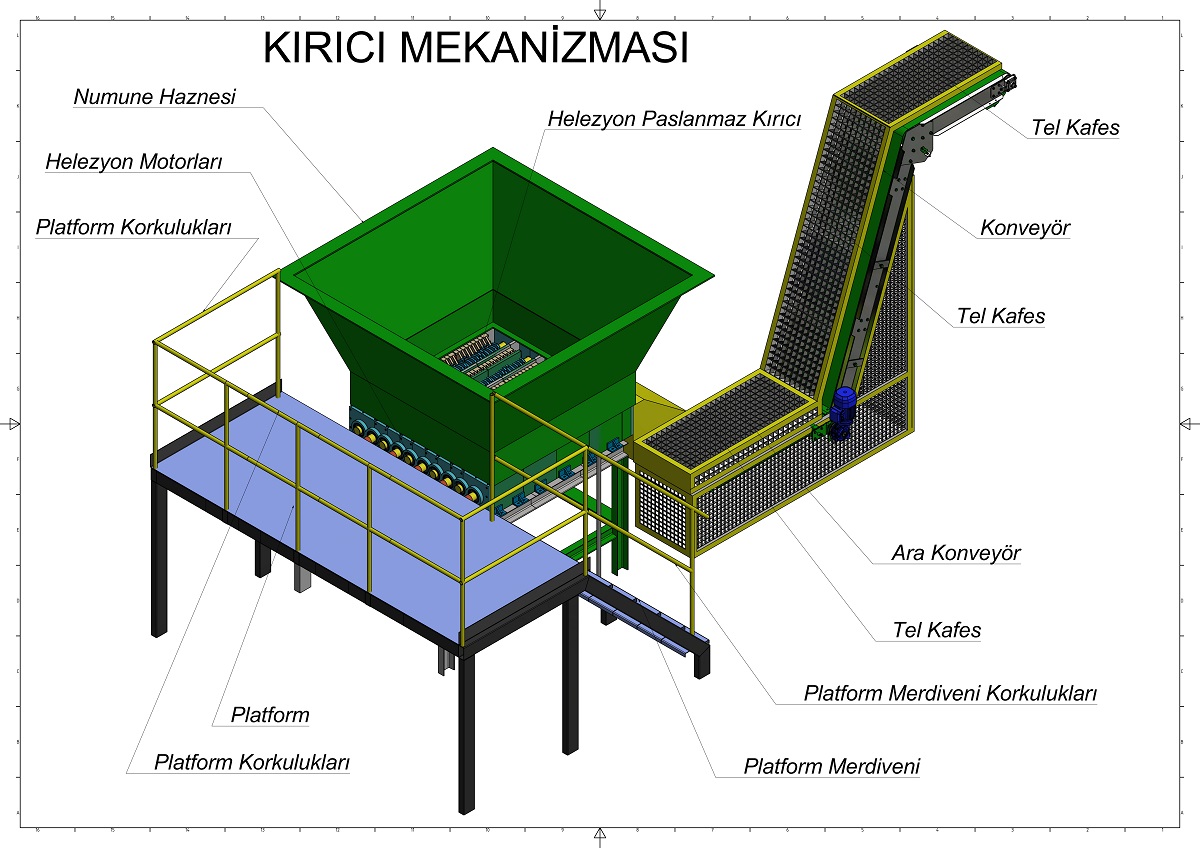

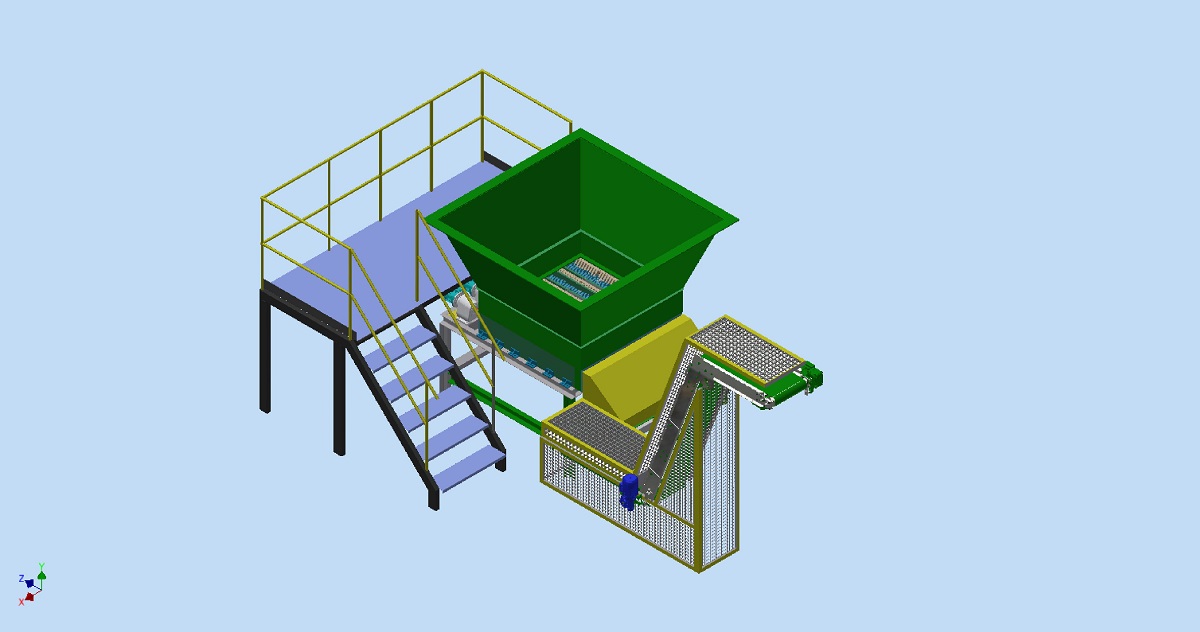

Take a brief look at our few projects below...

It is the most commonly used conveyor type. It is low cost and has a wide product transport spectrum. Depending on the design, there are capacities that can carry many different products in various sizes and weights and in various shapes.

30, 45, 60, 90, 135, 180 ° turn conveyors are used depending on the design requirements of the customer and the production line. They can be produced both in band and in roll. They are triggered.

They are usually used in food production lines. Chassis are made of stainless steel. The metal can be separated from the conveyor by a powerful metal detector mounted on top of the conveyor.

It functions the same as a flat belt conveyors, but it is much more useful in terms of ease of installation and maintenance. The band of the conveyor consists of modular diamonds. When the broken diamond is removed from its pins, the fault is eliminated. The modular tapes are also suitable for washing.

It is the most important element of feed and separation systems in the conveyor line. They are used to combine two different lines or to decompose them under certain conditions.

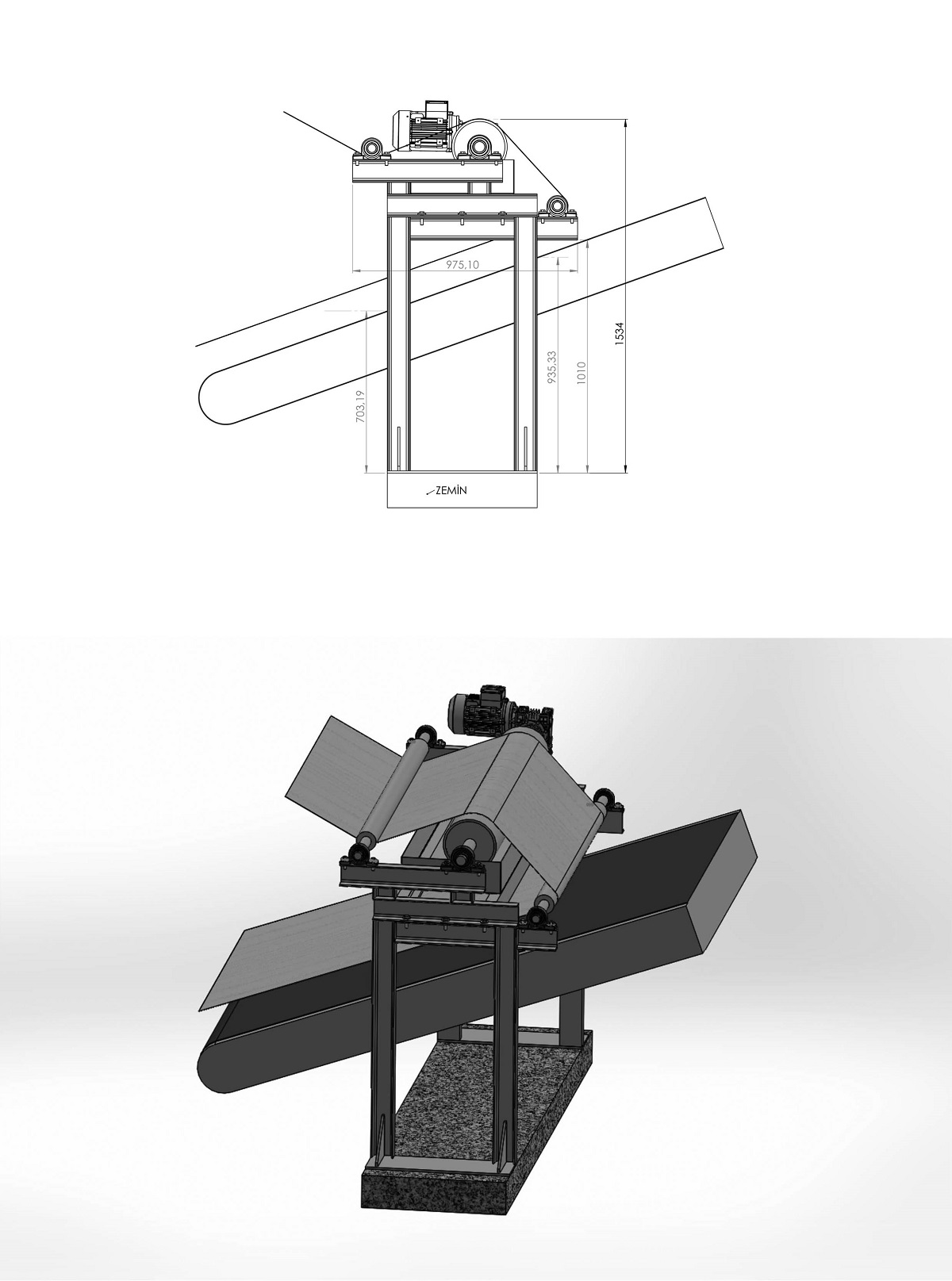

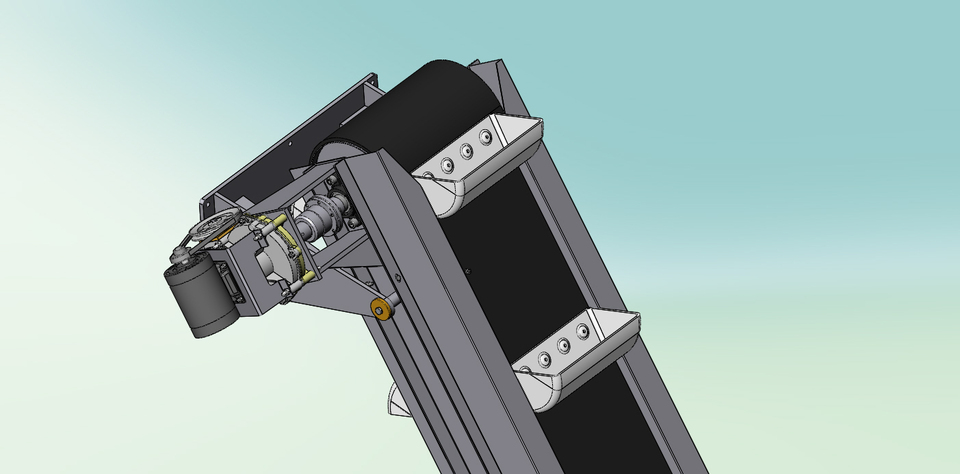

It is produced to transport small pieces of material to high levels. The obstacle on the belt prevents the conveyor working on the inclined plane from backing away.

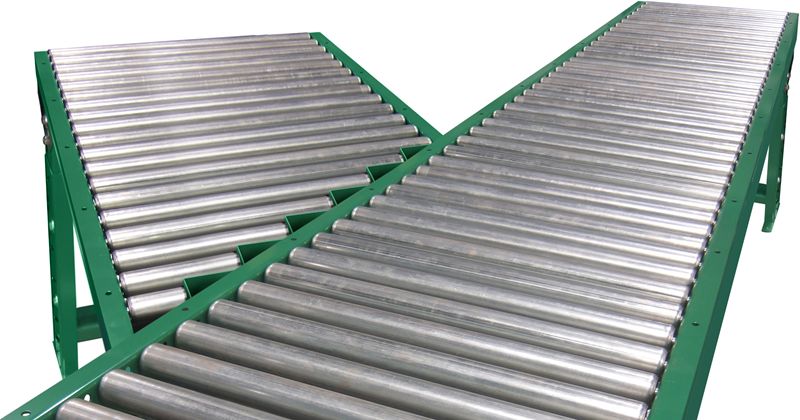

It is the type of conveyor that is formed by sequentially mounting rolls on a steel frame. They are used for horizontal conveyance of materials. Movement of the roller can be given by chain or belt power transmission. Maintenance and installation is very easy. The idle roller conveyors are non-driven conveyors, that is freely rotated conveyors without power transmission with any power unit. On these conveyors, the products can be conveyed either with the help of a human or on an inclined plane. In the case of power steering, the power unit and the power transmission means are used to drive the rollers and deliver the products to a spot. The roll diameters and length are determined according to the requirements, depending on the weight and volume of the cargo carried. Roller can be coated with Teflon or rubber according to the needs of the product and the customer. In this case, the friction coefficient between the product and the roll can be changed to any desired extent.

They usually run at low speeds. They have a weighbridge on them. Advantages of belt weighing conveyors are that they make more accurate and continuous measurements than banded ones. This measurement gives exact result.

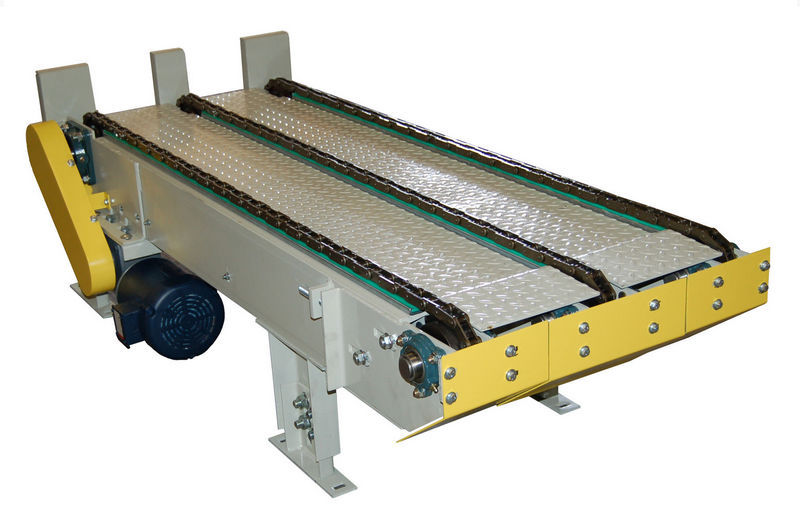

They are conveyors that allow pallets to be transported directly onto drive chains. They are usually used to transport heavy loads on conveyors.

Different models can be produced according to usage purpose.

- Standart Chain Conveyors

- Accumulating Chain Conveyors

- Double Speed Cain Conveyors

- Roller and Chain Conveyors.